Flowchart of the production of LED Vanity Mirrors

1. Cutting.

Workers cut large pieces of raw glass into different sizes according to order requirements

2. Polishing

Workers used a milling machine to smooth out the perimeter of the mirror.

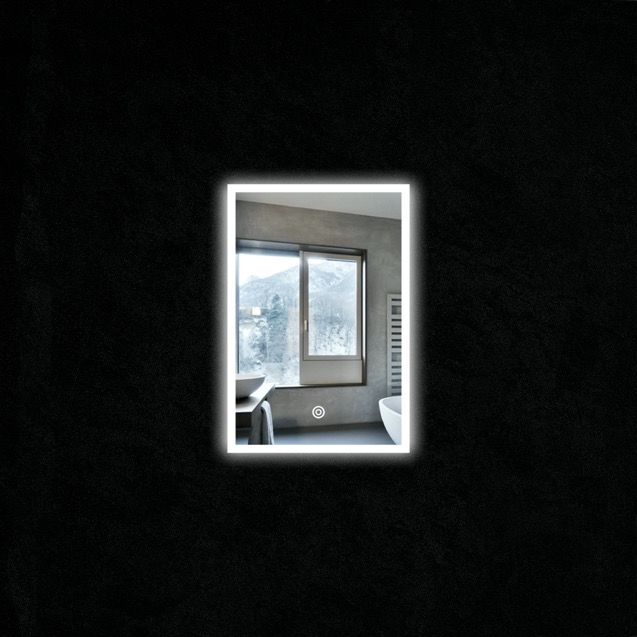

3. Sandblasting

Depending on the design, forest the mirror with different shapes. Please note

Not all mirrors need to be sand blasted .

4. Marking

Workers mark the back of the mirrors with on/off and defogging symbols through a laser marking machine, so consumers can control the mirror by clicking on the icon.

5. Assemble

Firstly, the workers mounted the LED strips onto the aluminium frames, then glued the frames to the back of the mirrors, followed by the installation of the electrical parts, and finally connecting the strips to the electrical boxes.

6. Inspection

Our QCs first check the surface of the mirror for scratches, the edges of the mirror are smooth, the labels are in the correct position, and finally plug it in to test if the LED lights work properly.

7. Packing

Mirrors that have passed the inspection will proceed to packaging. The clean mirror is firstly covered with a plastic bag and then placed in a one-piece polystyrene box with a lid. It is then placed in a 5-wallen reinforced carton. Finish with a plastic band for easy access.

Mirrors packaged and placed neatly on pallets for loading.